Location: Chicago, IL

Year Work Conducted: Multi-year project completed over 2021-2022

Membrane: Hot rubber and asphalt membrane

Total square feet: 45,000

Features: Residential towers, urban park and various amenities

One Chicago is a luxury mixed-use development that features two residential towers and a shared podium building. It stands tall, reaching 971 feet on the city’s iconic skyline with 812 residential units over two towers and 188,000 sq ft of retail center with a grocery, fitness center, restaurants and event center. Formerly One Chicago Square, One Chicago is among the tallest buildings in Chicago and totals 2,200,000 square feet, located where the Gold Coast and River North meet. One Chicago was designed in partnership between Goettsch Partners and Hartshorne Plunkard Architecture. The tower design created a new urban park that provides a buffer from street activity as well as a sanctuary and amenity for residents, patrons and the public.

International Leak Detection (ILD) was specified by the architect, engineer and facility owner, and provided multiple services over 2021-2022 on this new, high-end luxury construction.

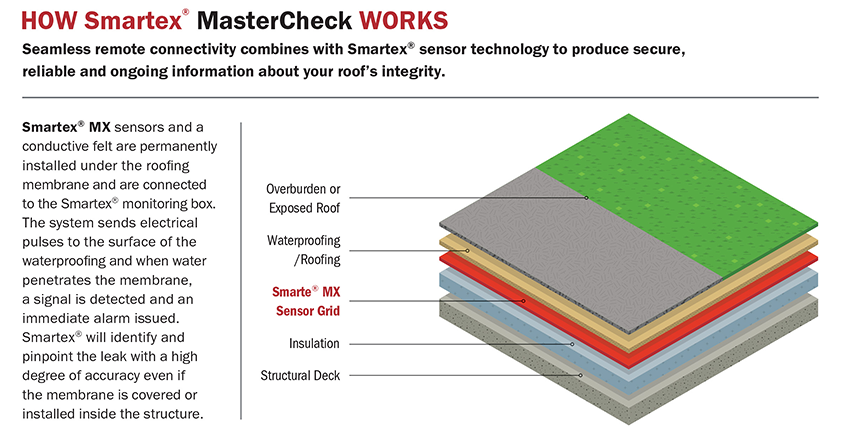

Intelligent Roof Monitoring

ILD’s premium Smartex® MX Mastercheck intelligent membrane monitoring system was installed over a waterproofed parking deck of One Chicago. When seamless remote connectivity combines with Smartex® sensor technology, it produces secure, reliable and ongoing information about the membrane’s integrity, providing early warning and timely notification of a breach by email or text. Smartex® can reduce long-term maintenance costs by up to 70%.

ILD also offers Smartex® DM Defensematch, an economical choice for proactive building owners, and Smartex® VT Vaportech, a moisture intrusion monitor suitable for new or retrofit roof projects.

EFVM Leak Detection

ILD was also contracted to provide leak detection on various levels of the tower including the garage, amenity areas, balconies and terraces following construction as a quality control measure on 45K square feet of hot rubber and asphalt membrane.

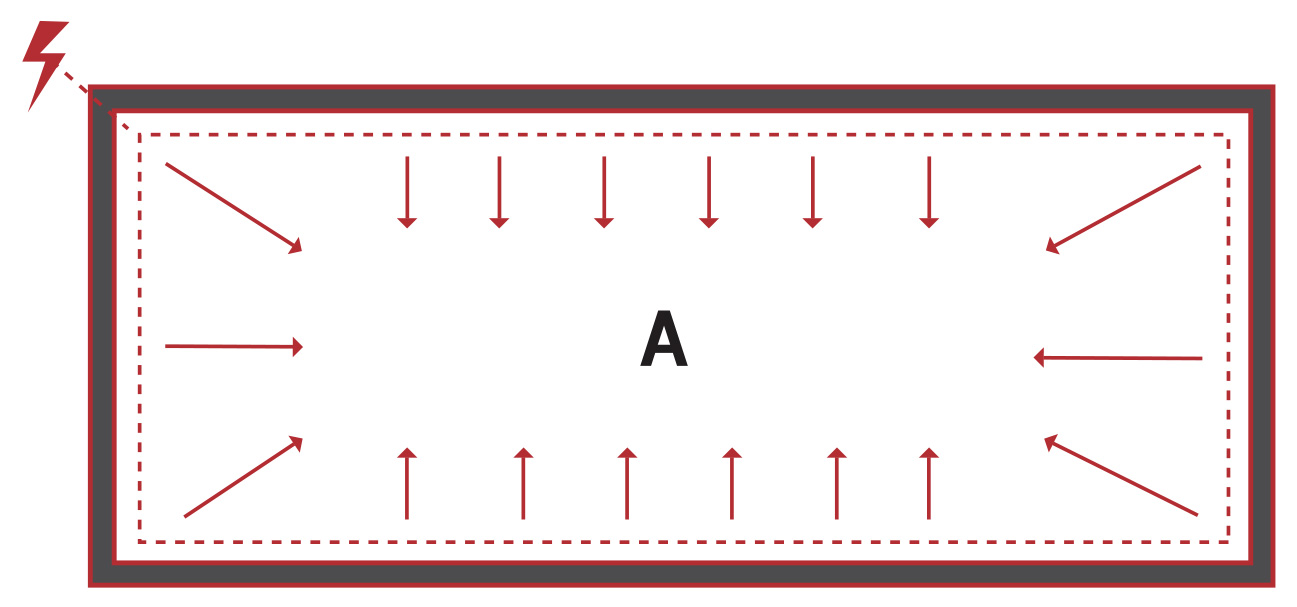

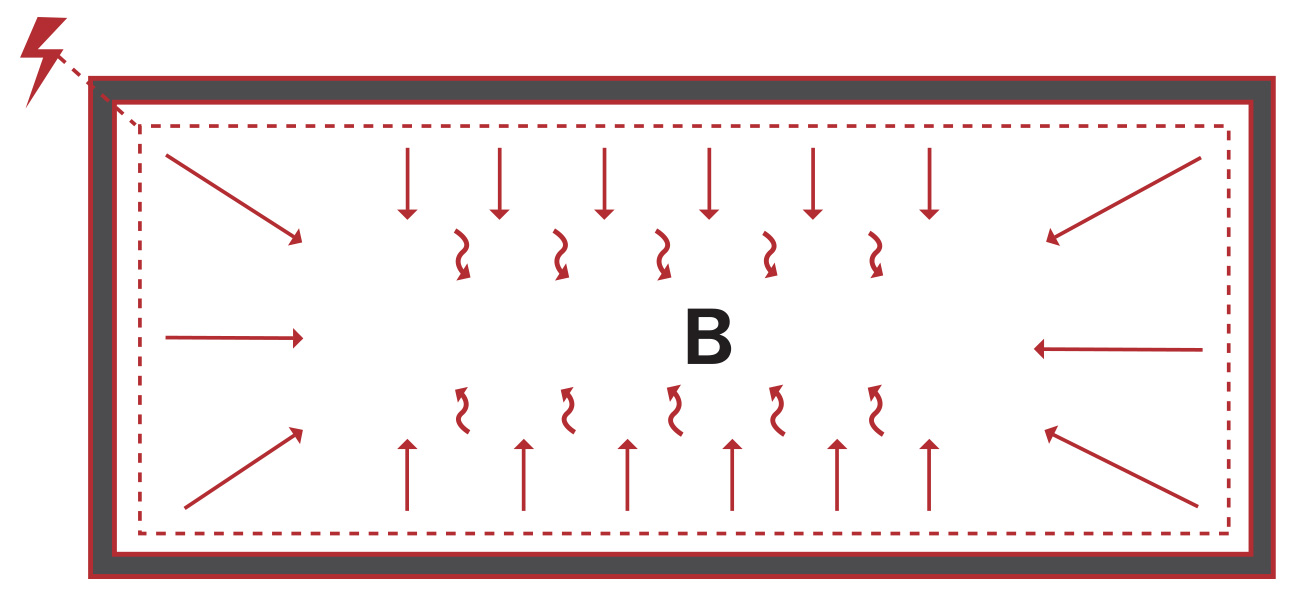

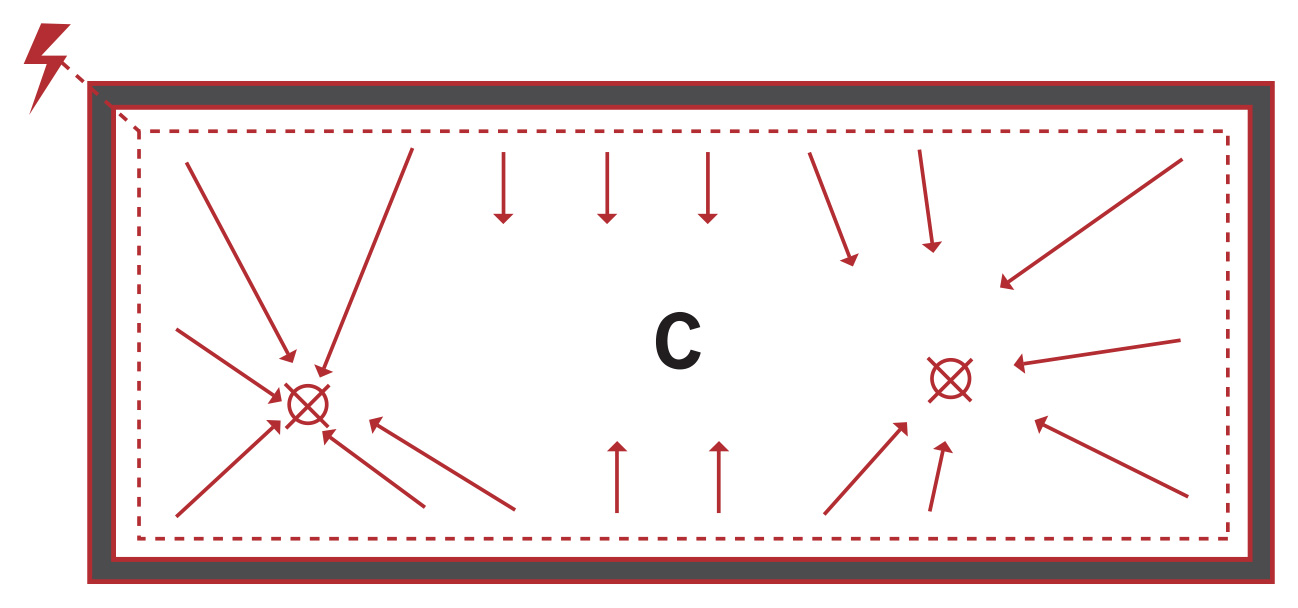

EFVM® is a low-voltage leak test method that creates an electrical potential difference between a non-conductive membrane surface and conductive structural deck or substrate, which is earthed or grounded. EFVM® is unique in its ability to test the integrity of waterproofing membranes with overburden or ballast. ILD certified inspectors performed non-destructive integrity tests on the new waterproofing membranes and containment liners of One Chicago.

A. Small electrical pulses are directed onto the membrane. The electricity searches for a ground connection.

B. If the membrane is watertight, the electricity is isolated and does not find a ground connection.

C. If the membrane is not watertight, the electricity makes a ground connection and is pulled towards positive poles.

At ILD, we appreciate our longstanding, repeat clients who value the careful and thorough approach we bring to our work. For over twenty years, we’ve been the leading provider of roofing and waterproofing integrity testing and intelligent monitoring systems, serving clients from offices and affiliated partners around the world helping companies to manage risk and identify issues.