Leading the Industry

ILD® IS THE WORLD LEADER IN ELECTRIC FIELD VECTOR MAPPING (EFVM®) TECHNOLOGY. WE CREATED IT. WE OWN IT.

EFVM® is a low-voltage leak test method that creates an electrical potential difference between a non-conductive membrane surface and conductive structural deck or substrate, which is earthed or grounded. Using ILD’s proprietary EFVM® technology, we can pinpoint leaks on vertical surfaces, flat surfaces and through overburden, green roofs or ballast.

HOW EFVM® WORKS

An electric field is created by applying water on the surface of the membrane and using the water as a conductive medium. The EFVM® equipment delivers a low voltage pulsating electrical charge between the non-conductive waterproofing membrane and the conductive structural deck.

A watertight membrane will isolate the potential difference, while breaches in the membrane will cause an electrical connection to occur. Our certified inspectors read the directional flow of the current with a potentiometer to locate the point of entry with pinpoint accuracy.

The EFVM® technicians then complete the test by conducting a visual inspection of all wall junctions, perimeter details, and membrane penetrations. All breaches are numbered to allow for repairs by the waterproofers onsite and are retested to confirm watertightness. A report follows with picture documentation of every breach and a detailed drawing noting the wire placement and breach locations.

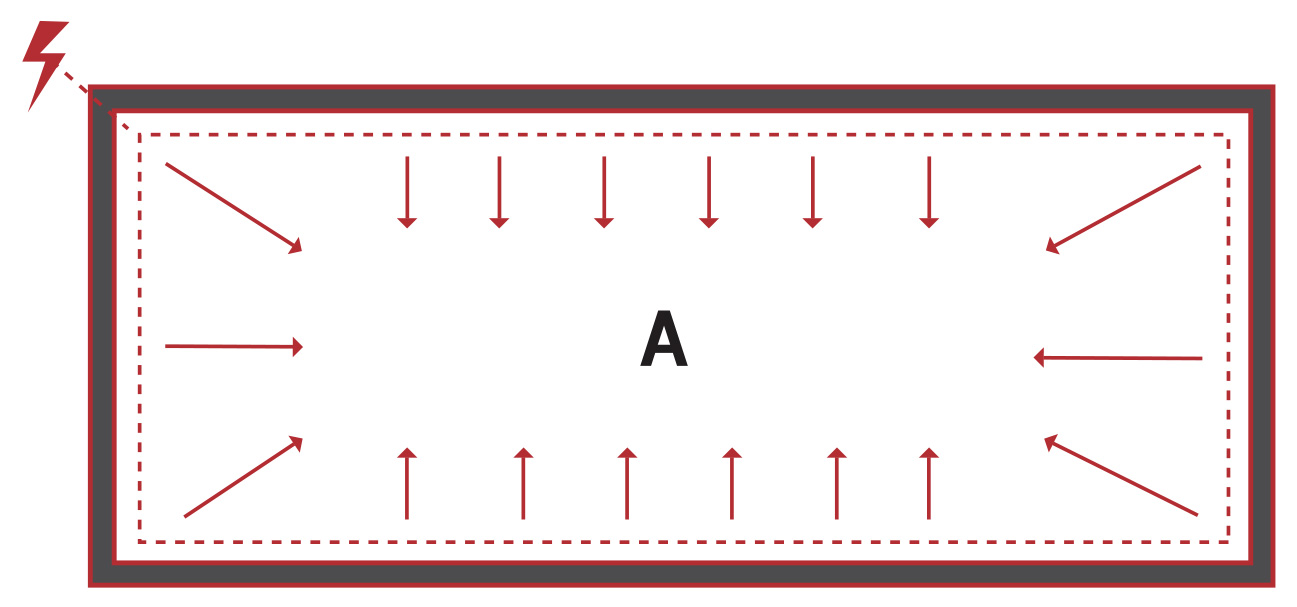

- Small electrical pulses are directed onto the membrane. The electricity searches for a ground connection.

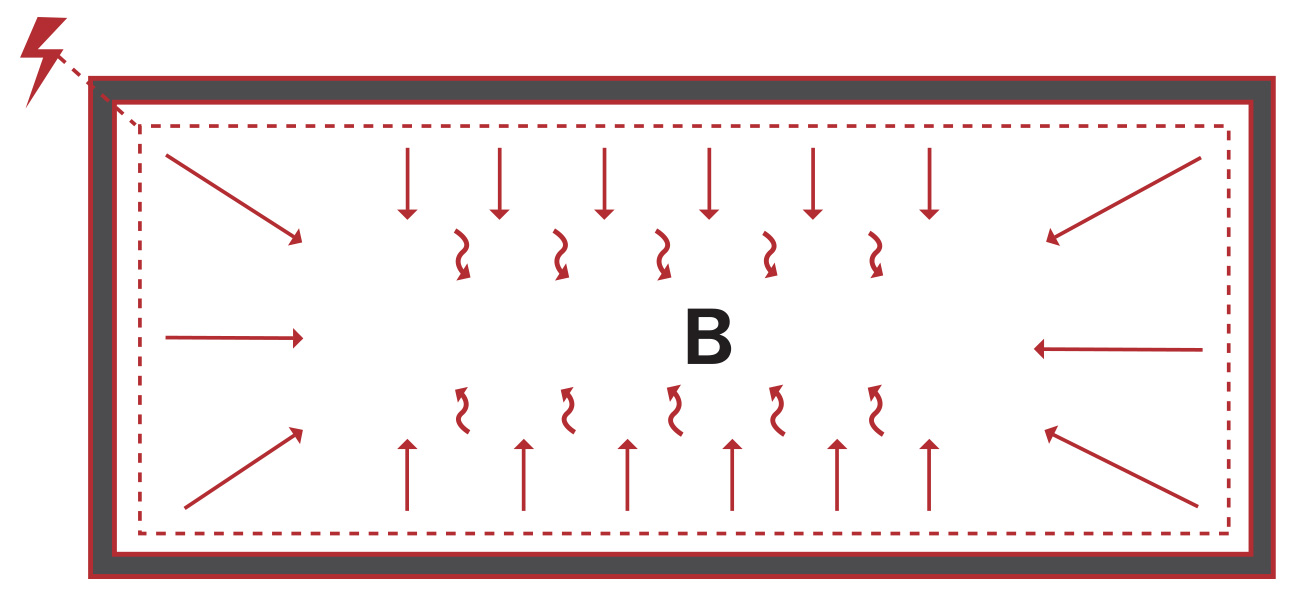

- If the membrane is watertight, the electricity is isolated and does not find a ground connection.

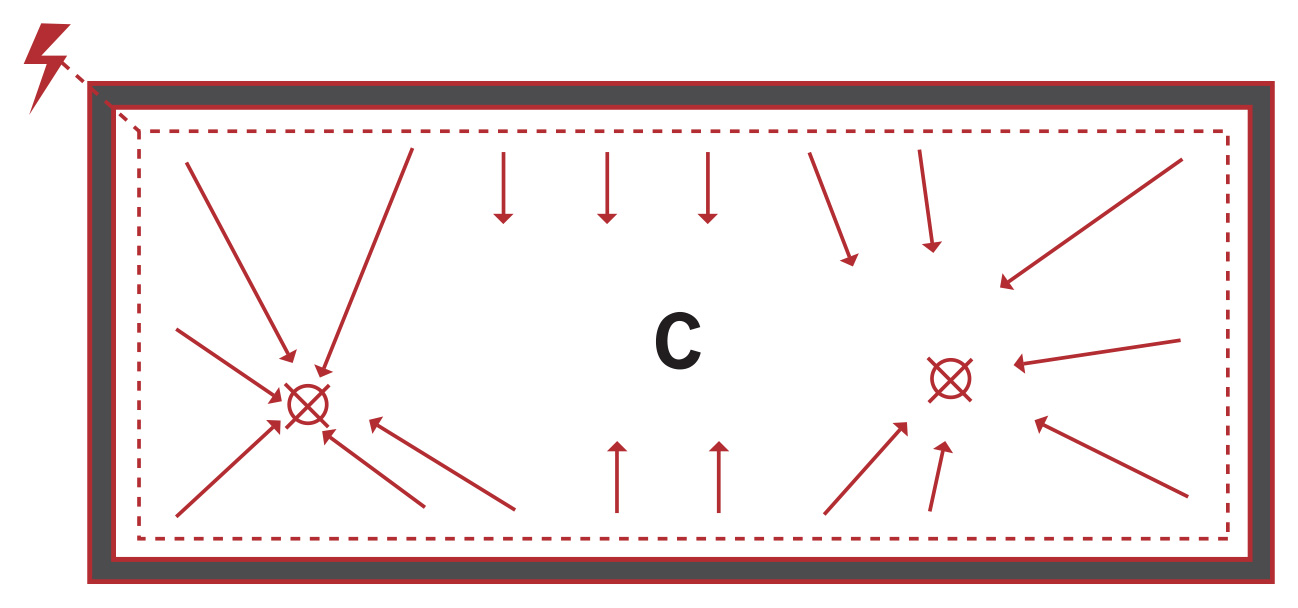

- If the membrane is not watertight, the electricity makes a ground connection and is pulled toward positive poles.

A. Small electrical pulses are directed onto the membrane. The electricity searches for a ground connection.

B. If the membrane is watertight, the electricity is isolated and does not find a ground connection.

C. If the membrane is not watertight, the electricity makes a ground connection and is pulled toward positive poles.

TOP 10 ADVANTAGES OF USING EFVM®:

- Effective on vertical surfaces

- Pinpoints the exact location of any membrane breaches

- Defects can be repaired and retested the same day

- Non-destructive to the membrane

- Requires only a limited use of water

- Eliminates removal of overburden to locate a breach

- Can be performed in inclement weather

- Can be performed on sloped structural decks

- Overburden installation can proceed immediately after or during test

- Membrane performance can be monitored through the overburden

- Developed by ILD® Germany in the early 1990s, EFVM® quickly became a valuable tool for leak investigations on existing systems. Introduced to North America in 2001, the EFVM® testing procedure has become the standard for waterproofing verification.

- ILD® has tested over 500 million square feet of membrane worldwide (including hot or cold liquid applied membranes, coatings, and various sheet membranes). Our certified inspectors perform non-destructive integrity tests on new or existing waterproofing membranes and containment liners using our pinpoint-accurate EFVM® technology.

- Only ILD® technicians are trained and certified in performing EFVM® testing, providing superior detection of all waterproofing defects and breaches (particularly in cases where water exit location may not correspond with point of entry).